Our solid carbide milling cutters and drills from our own production Discover now

Our offer at a glance

Top quality

Custom manufacturing of milling tools and step drills

Regrinding service

Our offer at a glance

Precision Tools & Grinding Services in Germany

We offer comprehensive services for cutting tools and precision tools, all manufactured with the highest quality in Germany. Our expertise includes:

- Tool Grinding: Precision grinding of your tools for optimal performance.

- Manufacture of Cutting Tools: Custom manufacturing of milling cutters, drills, and reamers tailored to your specific needs.

- Regrinding / Resharpening of Cutting Tools: Extend the life of your tools with professional regrinding services.

- Custom Tool Production: Tailor-made milling, drilling, reaming, and countersinking tools for your specific applications.

- Modification of Standard Tools: Custom adjustments to cutters, drills, and countersinks for unique applications.

- External and Internal Cylindrical Grinding: Precision grinding of external and internal diameters with the highest accuracy.

- Custom-Shaped Indexable Inserts: Production of indexable inserts designed to your specific requirements.

- Cutting of Carbide, HSS, and Ceramic Rods: Efficient and precise cutting of hard materials.

- Thread Grinding of Carbide and Hard Materials: Precision thread grinding technology for demanding materials.

- Surface Grinding: High-precision grinding of flat workpieces for perfect surface quality.

With our modern production facilities and experienced specialists, we guarantee the highest precision and quality, whether manufacturing new tools or refurbishing used cutting tools.

Rely on our expertise for custom solutions in tool grinding, precision manufacturing, and grinding services.

Top quality

If you value "Made in Germany" quality and fast, customized service, you’ve come to the right place. Our products are exclusively manufactured in Germany by skilled professionals using the latest machinery. Our suppliers for carbide and coatings are also based in Germany. This way, we guarantee you top quality at an excellent price-performance ratio.

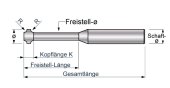

Custom manufacturing of milling tools and step drills

As an experienced manufacturer of milling tools, we implement your specific requirements quickly and flexibly. Instead of long waiting times, you benefit from our fast service, efficiently solving your machining challenges. We produce all types of solid carbide milling cutters, solid carbide drills, and cutting tools – even on short notice! Just let us know what you need, and we will develop the right custom tool for you.

Regrinding service

Our service doesn’t stop with the delivery of your tools; we are committed to ensuring you get long-lasting and cost-effective performance from them. Our standard tools can be resharpened up to ten times, maintaining their sharpness and precision throughout their entire lifespan. This is not only financially beneficial but also ensures you can always rely on the quality and performance of your tools.

Our resharpening service includes:

- Resharpening and reconditioning of standard and custom tools: Whether it's standard tools or special custom designs, we professionally sharpen and recondition all types of tools.

- Resharpening third-party tools: We also gladly resharpen tools from other manufacturers.

- Precision grinding on CNC machines: Your tools are sharpened on state-of-the-art CNC machines following certified ISO 9001 production standards, ensuring the same quality as with new tool production.

- Free return of tools no longer viable for resharpening: If a tool is no longer cost-effective to resharpen, we will mark it for you and return it free of charge.

Our goal is to ensure that your tools always deliver optimal performance without compromising sharpness or precision. This way, you can secure the long-term efficiency of your production while minimizing tool costs.